Injection Moulding

As the name implies Injection moulding is a manufacturing process for producing parts by injecting material into a mould. We have been providing Injection moulding service for many years. Should you need any inj. moulding services don’t hesitate to contact us directly for more information and free quote.

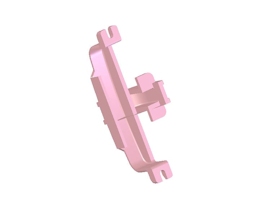

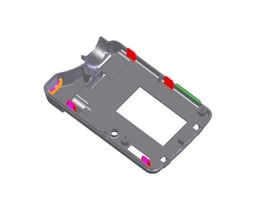

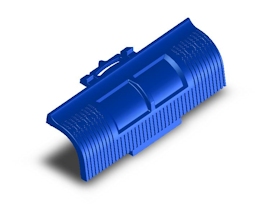

In general injection moulding can be performed with a host of materials, including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mouldmaker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars.

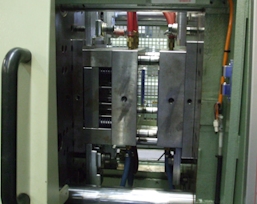

We (Panon Plastic) are a full service facility, offering injection molding with our or your mold.

From just a sample run to the full production we can offer our high speed and high precision equipment in a clean environment. While consistency is important we range presses from 40 to 120 ton. Mostly newer equipment means greater dependability and optimum molding.

To ensure properly processed materials we are equipped with desiccant dryers, hopper loaders and mold temperature control units. We have successfully processed: ABS, Acrylic, Acetal, Nylon, Noryl, Polycarbonate, Polyurethane, PP, PS , PE, PVC and Thermoplastic-Poliester.

Preventive mold maintenance is one of our many commitments toward maintaining high standards.

|

|